A pilot scale facility for extracting, analysing and optimising chemicals from biomass and process sidestreams with integral industrial biotechnology and a food grade environment.

The AberInnovation Biorefining Centre is home to BEACON Biorefining.

Capabilites include:

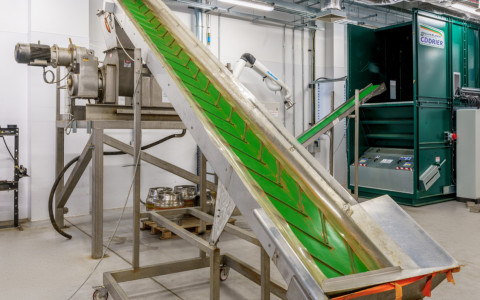

- Primary processing

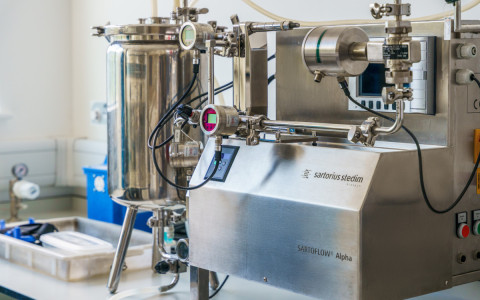

- Downstream processing

- Fermentation

- Clean room and product finishing

- Low carbon laboratory

With dedicated technical support staff, integrated advanced chemical analysis and Future Food Centre under the same roof, and access to Aberystwyth University's renowned academic expertise, the AberInnovation Biorefining Centre is the perfect place for your product and process development needs.

Find our Centre's technical specifications and an enquiry form via this page's sidebar.

Technical Features

Campus Features

Download Brochure

Contact Us